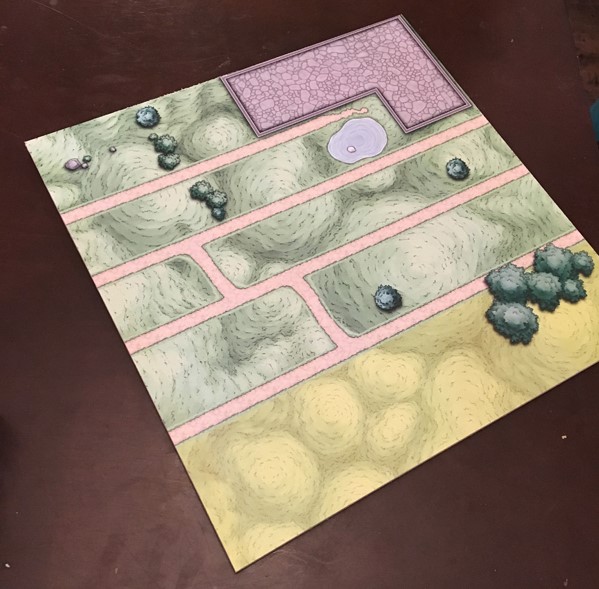

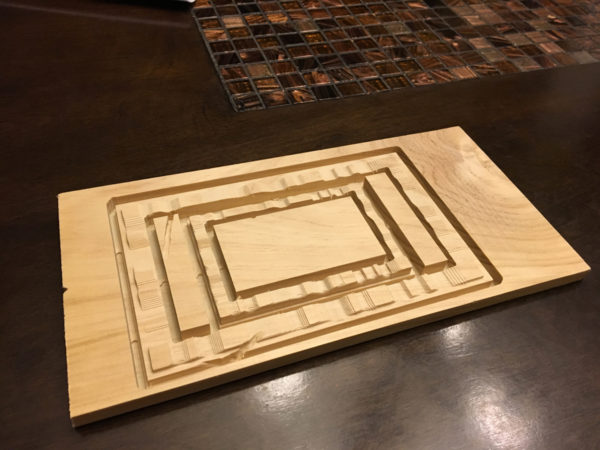

With the first two phases complete on my pimp out of Era: Medieval Age, it was time to move on to the next piece, the player boards. These boards were complained about a lot and is the only major piece of criticism with the game from what I see online. The publisher provided a sticker set to improve the overall visibility of the board numbers but I know we can do a lot better than that. Also, it doesn’t change the fact that the boards are such bland and uninspiring yellow.