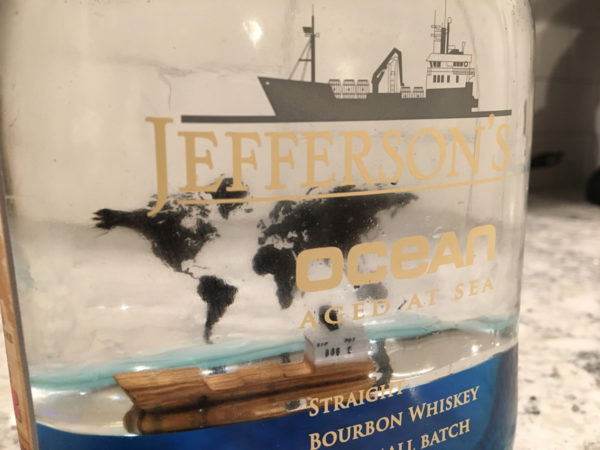

As a side project, I decided I wanted to mess around the “ship in a bottle” concept. It came from the last minute decision not to throw away our empty bottle of Jefferson’s Ocean from Gen Con. This whimsical decision ended up leading me down a path of the act of bottling a ship (not for the faint of heart or shaky of hands) and eventually to a CNC project and some science with the kids.

It began with the idea of putting a ship in a bottle but the chosen bottle made for a lot of challenges and I didn’t want to dive into the deep end of that hobby for my first project. Over the summer, the kids brought home one of those “wave in a bottle” craft projects and since I didn’t think I could stick a boat in there, I decided to make the simple wave project.

After having lunch with a friend, he had some scrap wood to give me and we started talking about my bottle project and one of the scraps was a bourbon barrel stave. What soon began as “wouldn’t it be cool…” led to the planning out of the rest of the project.

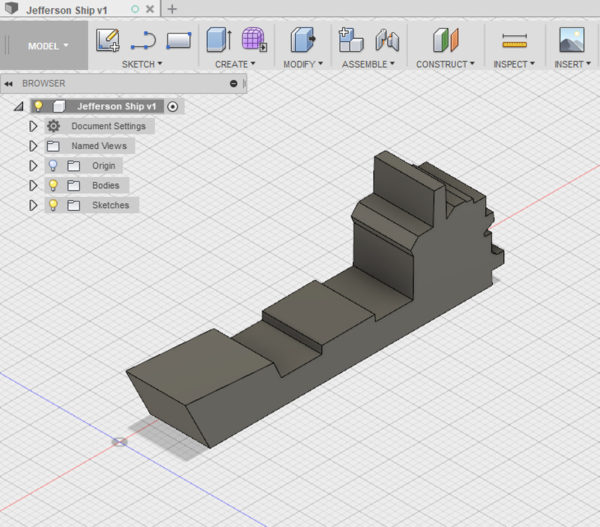

As I showed off a while back, I went into my CAD program and made a rough outline of the Jefferson’s Ocean logo then printed a test out. The sizing was a bit tight so I reworked the model a couple of times then got to work on the real deal.

Cutting a 7mm slice from the thick piece of the stave, I had a nice cross-section of the barrel wood with char on top and the outside of the barrel on the bottom.

I decided I wanted to have the most appropriate part of the American White Oak stave feature on the model so I left the char portion to be the hull of the vessel.

The CNC cut it a little rough but I sanded it down smooth and polished it up for the final touches.

To give the boat some character, I painted it up and then sealed the piece in an acrylic to help protect it from the eventual corrosion of the liquids I’d use to make the “wave.”

At this point, it was time to get a little science-y. The two liquids you need to make a “wave bottle” are water and baby oil. The densities of these two are 1.0 g/cm3 and 0.83 g/cm3 respectively. The average density of American White Oak is 0.77 g/cm3. The basic properties of each of these elements mean they will not mix so what gives the wave-like effect is the water being more dense than the baby oil and the oil then floats on top. Unfortunately, my oak stave is less dense than both so if I wanted to create the illusion of a boat floating on the “ocean,” I’d need to increase my density to the point that it is more dense than baby oil but less dense than water.

This problem actually works out in my favor as the boat itself has some major issues as well. The boat being just a profiled image of a real boat means it doesn’t share any of the real displacement aspects of a real boat and, most importantly, doesn’t have the balance a real boat has when floating. Suffice to say, if oak had that critical density lying between water and baby oil, it’d list heavily on its side. Or, when I actually did my initial experiment, it would float upside down because the char side of the wood is even less dense than the rest of the wood.

The obvious solution to increasing the density of my boat is to add more weight, in this case an element with more density than water to bring my boat down to float in between. I settled on brass because I had some from my modelling kit and because it has a pretty high density (8.73 g/cm3). Stainless steel (8.05 g/cm3) from a paper clip would have been another option but I was worried about rust eventually causing an issue. I toyed with Aluminum (2.70 g/cm3) as well because brass can also corrode but I would have had to add a lot of Aluminum to the boat to get it where I needed it and I didn’t have that on hand in a form I could easily model.

With brass’ high density, it didn’t take much to get the boat where I needed. Two small rods were all it took and the boat achieved that perfect balance that we needed. Placement would now become critical because even though we have the right total density of the boat to float in between the two mediums, if not placed well, it would list or upend or otherwise float unboat-like and that would do us no good. Placing the rods are the aft and stern of the model, parallel to the long run of the hull (and centered on the model) made the dense brass rods pull the boat model down rest evenly on it’s hull and act most excellently like a boat.

Blue food dye was added to the water, then I added most of the baby oil, then finished with the sealed and weighted boat stave. It came together very well and made for a fun science project.

E

That’s awesome!

Christian

Thanks! It was a lot of fun!